TECHNOLOGY TRANSFER

KNOW-HOW TRANSFER

TECHNOLOGY

IMPLEMENTATION

TO LOCAL

ENVIRONMENT

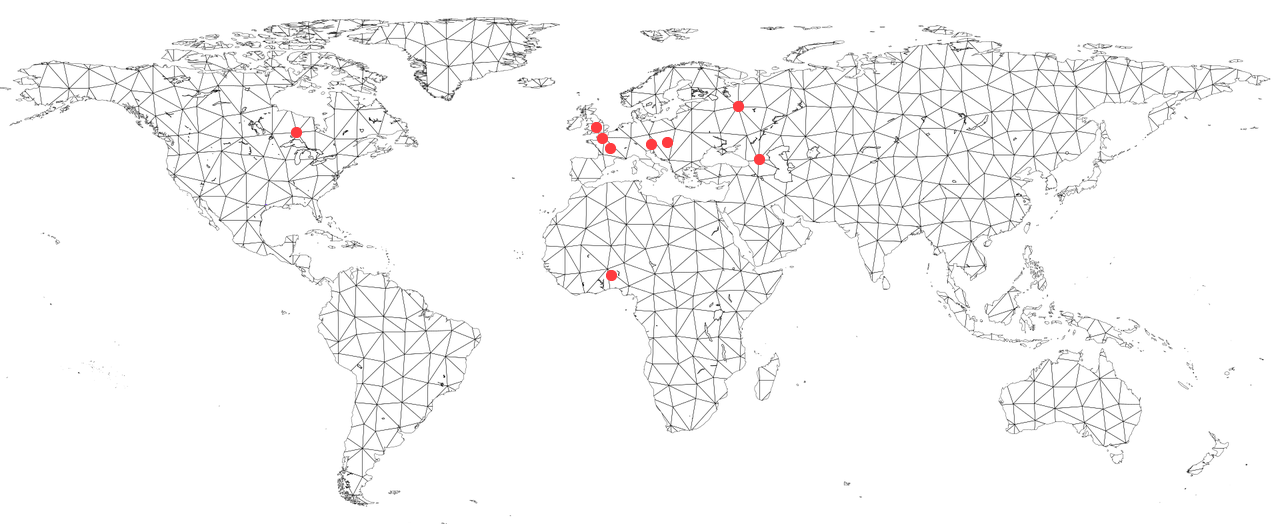

From Canada to Nigeria, the connection system of NISIO Group networks the world.

We make both old and new technologies available everywhere. Positioning ourselves and our brand as a bridge, we connect demand to the supply of technologies in a bid to create a better world for everyone.

We hope our next project will be yours, for a sustainable future!

ABOUT

TECHNOLOGY

TRANSFER

NISIO Group is a solution-based company targeted toward achieving many high-demand solutions. It is an underlying effect of the following: we have positioned ourselves as a trusted partner and channel for the movement of data, designs, inventions, materials, software, technological knowledge, or trade secrets from one organization, country, and continent to another.

We make sure to align ourselves with the policies, procedures, and values of the organizations and the countries we work with to make them satisfied.

MARKET

DEMANDS

We recognized that the technology transfer to Nigeria and Africa is dominated by the West and Asia (mainly China, Korea, and India). NISIO Group’s mission is to make Nigeria and Africa self-sufficient technologically. As one of Africa’s largest market, there are still many solutions to be introduced to the Nigerian market. We make a lot of identification, channeling, and access from inventions to solutions.

PPPP

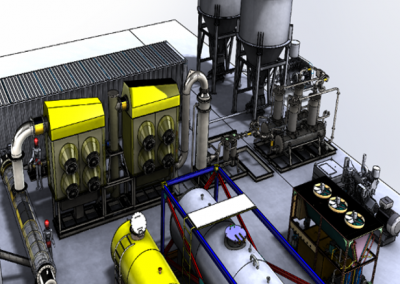

Plastic Pyrolysis Power Plant

Plastic waste is a problem. The natural degradation of plastics can be more than 500 years. Deposal is not effective in the long term and waste mountains are sources of infection. Despite the regulations, waste incineration can still be very harmful to the environment.

As a solution, plastic pyrolysis technology is available, which produces valuable energy sources from waste. The unique implementation of this technology is the result of 13 years of development. The process is closed, it does not have any harmful emissions. The products of the technology are 70% oil, 20% gas and 10% of coal. All of these can be stored and utilized directly or after some refinement as fuel for engines or forges.

The technology does not require external energy input, it can cover its own consumption from pyrolysis products. This feature makes PPPP suitable for island mode operation in rural areas.

G-Bubbles

Foam gravel from waste glass

With a unique technology, foam gravels with advantageous physical properties can be produced from waste glass to substitute conventional gravel in concrete. The usage of recycled lightweight aggregates has a considerable environmental advantage.

The physical properties of lightweight concrete with G-Bubbles can be set in a wide range. Concrete is pumpable, the whole structure becomes cheaper. Net weight is reduced by 20%, the thermal and noise insulation capacity is increased by 84% and 18% compared to conventional concrete.

Apart from concrete aggregate, there are other utilization possibilities of foam gravels. Due to the sound-absorbing properties, they can be used to prepare sound barrier walls. Thanks to their good thermal insulation capacity, they are particularly suitable for underfloor heating or facade insulation.

PPPP

Plastic Pyrolysis Power Plant

Plastic waste is a problem. The natural degradation of plastics can be more than 500 years. Deposal is not effective in the long term and waste mountains are sources of infection. Despite the regulations, waste incineration can still be very harmful to the environment.

As a solution, plastic pyrolysis technology is available, which produces valuable energy sources from waste. The unique implementation of this technology is the result of 13 years of development. The process is closed, it does not have any harmful emissions. The products of the technology are 70% oil, 20% gas and 10% of coal. All of these can be stored and utilized directly or after some refinement as fuel for engines or forges.

The technology does not require external energy input, it can cover its own consumption from pyrolysis products. This feature makes PPPP suitable for island mode operation in rural areas.

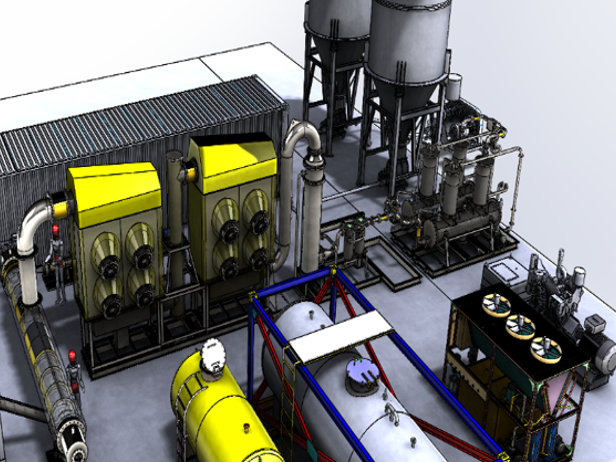

Incineration Power Plant

A known concept with new solutions

Accumulating waste is a striking phenomenon in both developing and developed countries. To address this, there are proven technologies in many parts of the world that need to meet ever-changing environmental requirements and increasing amounts of waste. For this reason, continuous technological developments are needed.

With 13 years of operation experience, a repetition of an existing incineration power plant can be established in a country in need. This plant meets all the EU requirements and applies the best available technology after a 6-year development and design period. It operates with a unique, closed burning system with low emissions. Based on the operating plant, the technology ensures high profitability and promotes environmental protection with 40-350 MW electricity capacity. One part of the incineration plant is a biogas plant which produces biogas from animal carcasses and other organic residues, thereby reducing biological hazards.

All the necessary knowledge, calculations, drawings are available for the highly efficient design, construction, permitting and operation of the incineration power plant.

Incineration Power Plant

A known concept with new solutions

Accumulating waste is a striking phenomenon in both developing and developed countries. To address this, there are proven technologies in many parts of the world that need to meet ever-changing environmental requirements and increasing amounts of waste. For this reason, continuous technological developments are needed.

With 13 years of operation experience, a repetition of an existing incineration power plant can be established in a country in need. This plant meets all the EU requirements and applies the best available technology after a 6-year development and design period. It operates with a unique, closed burning system with low emissions. Based on the operating plant, the technology ensures high profitability and promotes environmental protection with 40-350 MW electricity capacity. One part of the incineration plant is a biogas plant which produces biogas from animal carcasses and other organic residues, thereby reducing biological hazards.

All the necessary knowledge, calculations, drawings are available for the highly efficient design, construction, permitting and operation of the incineration power plant.

FURTHER SERVICES